Industrial boilers are large-scale heating systems used in manufacturing facilities, power plants, and other industrial settings. They generate high-temperature steam or hot water for various processes, including chemical processing, Geração de energia, and heating buildings. Neste artigo, we will discuss the different types of industrial boilers, their applications, and the maintenance practices required to ensure their efficiency and safety.

Introdução

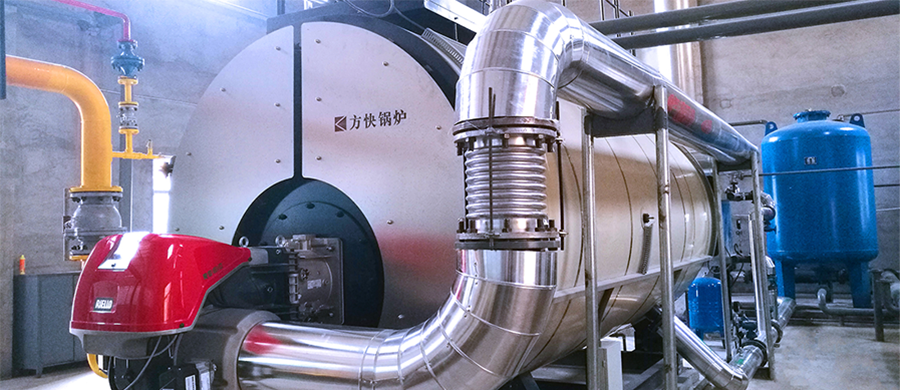

An industrial boiler is a complex system that consists of various components, including the boiler itself, burners, controls, pumps, and piping. The primary function of a boiler is to heat water to generate steam or hot water for industrial processes. The type of boiler used in an industrial setting depends on several factors, such as fuel type, energy efficiency, and cost-effectiveness. Industrial boilers can be fuelled by various sources, Incluindo gás natural, carvão, óleo, biomassa, and waste heat.

Precisa de uma nova caldeira?

Types of Industrial Boilers

There are several types of industrial boilers, each with its own advantages and disadvantages. The most common types of industrial boilers include:

Fire-tube Boilers

Fire-tube boilers are the oldest and simplest type of boiler, and they are still widely used in industrial settings. They consist of a large cylindrical shell that contains water and steam, with a series of tubes running through it. The tubes are surrounded by the hot gases produced by the burner, which transfer heat to the water. Fire-tube boilers are relatively inexpensive, easy to operate, and suitable for small to medium-sized applications.

Water-tube Boilers

Water-tube boilers are a more modern type of boiler that is commonly used in large-scale applications. They consist of a series of tubes that contain water and steam, with hot gases flowing over them. Water-tube boilers are more complex and expensive than fire-tube boilers, but they are more efficient and can handle higher pressures and temperatures.

Caldeiras Elétricas

Electric boilers use electricity as the primary source of heat, and they are commonly used in small to medium-sized applications. They are relatively quiet, eficiente, and require little maintenance, but they can be expensive to operate compared to other types of boilers.

Biomass Boilers

Biomass boilers are fueled by organic materials, such as wood chips, sawdust, or agricultural waste. They are a renewable and sustainable source of energy, and they are commonly used in the food processing and paper industries.

Waste Heat Boilers

Waste heat boilers are used to recover heat from industrial processes and recycle it to generate steam or hot water. They are commonly used in industries such as cement, steel, and glass manufacturing.

Package Boilers

Package boilers are pre-assembled and pre-wired boilers that are ready to use upon installation. They are commonly used in small to medium-sized industrial applications that require quick and easy installation.

Receba orçamentos de caldeiras GRATUITOS

Obtenha cotações de caldeiras locais GRATUITAS hoje

Compare os melhores preços

Economize dinheiro em sua nova caldeira hoje!

Industrial Boiler Applications

Industrial boilers are used in a wide range of applications, Incluindo:

Chemical Processing

Industrial boilers are also widely used in the chemical processing industry to generate steam or hot water for various processes, such as distillation, evaporation, and chemical reactions. o processamento químico industry is a diverse and complex industry that requires high-temperature and high-pressure steam for various processes.

Geração de energia

Power plants use industrial boilers to generate steam or hot water to drive turbines and produce electricity. There are different types of power plants, such as coal-fired, natural gas-fired, and nuclear power plants, each requiring different types of boilers.

Food Processing

Industrial boilers are used in the food processing industry to sterilize equipment, pasteurize products, and cook food. Food processing boilers must comply with strict hygiene and safety regulations.

Paper and Pulp Industry

Industrial boilers are used in the paper and pulp industry to generate steam for various processes, such as drying and pulping. The paper and pulp industry requires large amounts of energy, and boilers are an essential component of their energy supply.

Healthcare Facilities

Hospitals and other healthcare facilities require steam for various applications, such as sterilization and heating. Industrial boilers are used to provide a reliable and efficient source of steam for these facilities.

Procurando caldeiras com fabricação sofisticada, otima qualidade?

A caldeira Fangkuai sempre pode fornecer o que você deseja.

Industrial Boiler Maintenance

Regular maintenance is essential for industrial boilers to ensure their efficiency, safety, and reliability. The following are some of the maintenance practices required for industrial boilers:

Regular Inspection and Cleaning

Industrial boilers should be inspected and cleaned regularly to ensure that they are functioning properly and to prevent any potential problems. Regular inspection and cleaning can also help to identify any issues before they become major problems.

Tratamento de água

Water treatment is essential for industrial boilers to prevent corrosion, scale buildup, and other issues that can affect their efficiency and lifespan. Water treatment includes various processes, such as softening, desaeração, e tratamento químico.

Combustion Analysis and Adjustment

Boiler combustion should be analyzed and adjusted regularly to ensure that it is functioning efficiently and safely. Combustion analysis includes measuring various parameters, such as oxygen levels, carbon monoxide levels, and flue gas temperature.

Fuel Monitoring and Management

Fuel monitoring and management are essential to ensure that the boiler is operating at optimal efficiency and to prevent any potential safety issues. Fuel management includes monitoring fuel usage, analyzing fuel quality, and ensuring that the fuel supply is adequate.

Safety Controls and Alarms

Industrial boilers should have various safety controls and alarms to prevent any potential safety hazards. Safety controls and alarms include low water cutoffs, pressure relief valves, and flame detectors.

Conclusão

Industrial boilers are essential components of many industrial processes, and their efficiency, safety, and reliability are crucial for the success of these processes. Understanding the different types of industrial boilers, their applications, and the maintenance practices required can help industrial facilities operate their boilers efficiently and safely.

What is an industrial boiler?

perguntas frequentes

- What is an industrial boiler?

- An industrial boiler is a large-scale heating system used in manufacturing facilities, power plants, and other industrial settings to generate steam or hot water for various processes.

- What are the different types of industrial boilers?

- The different types of industrial boilers include fire-tube boilers, water-tube boilers, caldeiras elétricas, caldeiras de biomassa, waste heat boilers, and package boilers.

- What are industrial boilers used for?

- Industrial boilers are used in various applications, including chemical processing, Geração de energia, food processing, paper and pulp industry, and healthcare facilities.

- How do you maintain an industrial boiler?

- Industrial boilers require regular maintenance, including inspection and cleaning, tratamento de água, combustion analysis and adjustment, fuel monitoring and management, and safety controls and alarms.

- Why is industrial boiler maintenance important?

- Industrial boiler maintenance is important to ensure the efficiency, safety, and reliability of the boiler and to prevent any potential problems or safety hazards.