Introdução

Condensing gas boilers have become a popular choice for home heating and hot water systems in recent years, with many homeowners opting for them over traditional boilers due to their efficiency and environmental benefits. These boilers work by condensing water vapor in the exhaust gases, which results in a higher rate of heat transfer and a reduction in fuel consumption. Neste artigo, we will take a closer look at the features and benefits of condensing gas boilers, their limitations and the maintenance required to keep them running smoothly.

Obtenha um preço fixo online em 20 segundos:

What is a condensing gas boiler?

A condensing gas boiler is a high-efficiency heating system that utilizes advanced technology to extract additional heat from the flue gases produced during the combustion process. This type of boiler is designed to recover latent heat that is normally lost in traditional boilers. The recovered heat is then used to preheat the incoming water, resulting in increased energy efficiency and lower fuel costs.

best condensing oil boiler

How does a condensing gas boiler work?

Condensing gas boilers work by extracting additional heat from the flue gases produced during the combustion process. These boilers are designed with a secondary heat exchanger that captures the latent heat that would normally be lost in traditional boilers. o heat exchanger uses the recovered heat to preheat the incoming water, resulting in increased energy efficiency and reduced fuel costs.

Precisa de uma nova caldeira?

Benefits of using a condensing gas boiler:

- Increased energy efficiency:Designed to extract more heat from the flue gases produced during combustion. This results in increased energy efficiency and reduced energy costs.

- Lower emissions: Condensing gas boilers produce lower emissions than traditional boilers. This makes them a more environmentally friendly heating option.

- Improved reliability: Condensing gas boilers are designed with advanced technology, which results in improved reliability and reduced maintenance costs.

- Cost savings: The increased energy efficiency of condensing gas boilers leads to lower fuel costs, which can result in significant cost savings over time.

Factors to consider when choosing a condensing gas boiler:

- Size: It’s important to choose a condensing gas boiler that is appropriately sized for your heating needs. A boiler that is too small will not provide enough heat, while a boiler that is too large will waste energy.

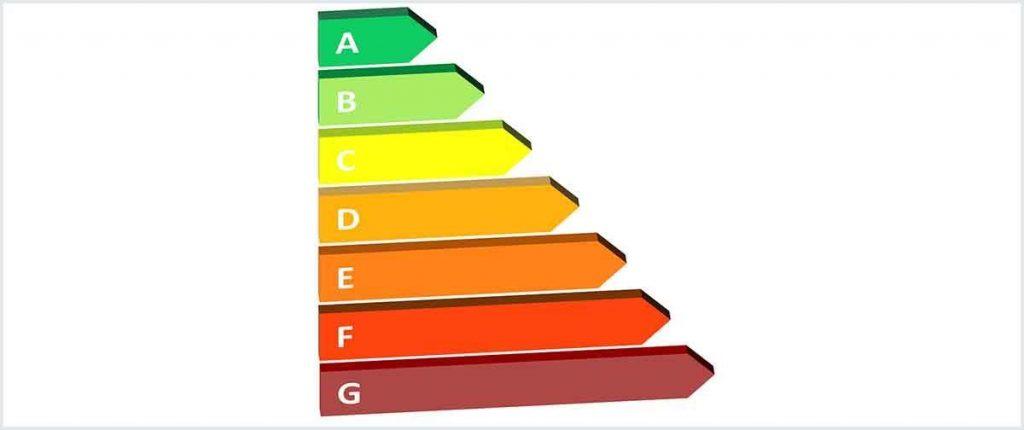

- Eficiência: The efficiency of a condensing gas boiler is measured by its annual fuel utilization efficiency (AFUE) rating. The higher the AFUE rating, the more efficient the boiler.

- Features: When choosing a condensing gas boiler, it’s important to consider the features that are important to you. Some boilers come with advanced features such as programmable thermostats, energy-saving modes, and remote control capabilities.

Most Efficient Condensing Gas Boiler

How efficient are condensing gas boilers?

Condensing gas boilers are considered to be highly efficient in terms of energy utilization. They have an average efficiency rate of around 90% or higher, which is significantly higher than older boilers that typically have an efficiency rate of 60-70%.

The high efficiency of condensing boilers is due to their unique design that allows for the recovery of heat from the flue gases, which would otherwise be lost in traditional boilers. This heat recovery process results in a higher overall energy utilization rate, which leads to lower fuel consumption and reduced carbon emissions.

Adicionalmente, modern condensing boilers are designed to operate at lower temperatures, which further improves their efficiency. This is because low temperature operation enables the heat exchanger to extract more heat from the flue gases, reducing the amount of waste heat that is released into the atmosphere.

It’s worth noting that the efficiency of condensing boilers can vary depending on several factors, such as the age and maintenance of the unit, the quality of the installation, and the type of fuel being used. To ensure that you are getting the maximum energy efficiency from your condensing boiler, it is important to have it installed by a professional and to have it serviced regularly.

Receba orçamentos de caldeiras GRATUITOS

- ✔Obtenha cotações de caldeiras locais GRATUITAS hoje

- ✔Compare os melhores preços

- ✔Economize dinheiro em sua nova caldeira hoje!

How much is a condensing gas boiler?

The cost of a condensing gas boiler can vary greatly depending on several factors, such as the size of your home, the type of boiler you choose, and the location where you live. Na média, you can expect to pay anywhere from $2,500 para $7,500 for a mid-efficient condensing gas boiler. No entanto, high-efficient models can cost upwards of $10,000 or more. Adicionalmente, the cost of installation can also add significantly to the total cost. It’s best to consult with a professional heating and cooling contractor to get a more accurate estimate based on your specific needs and budget.

Conclusão

Condensing gas boilers are a highly efficient and cost-effective option for heating homes and commercial properties. By extracting additional heat from the flue gases produced during the combustion process, these boilers can provide increased energy efficiency and lower energy costs. When choosing a condensing gas boiler, it’s important to consider factors such as size, eficiência, and features to ensure that you find the best option for your heating needs. Investing in a condensing gas boiler is a smart choice for anyone looking to improve their heating system and reduce their energy costs.

Procurando caldeiras com fabricação sofisticada, otima qualidade?

A caldeira Fangkuai sempre pode fornecer o que você deseja.