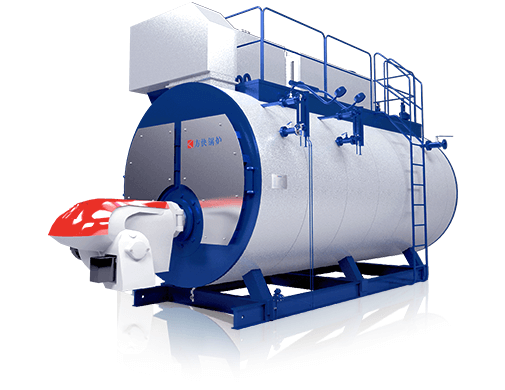

Gas(oil) Fired Integrated Steam Boiler The series of boilers adopts an excellent design concept. Through the condensing device, the heat of the flue gas is used in cascade, and the residual heat in the flue gas is fully absorbed, so that the boiler efficiency is greatly improved.

Rated thermal power: 1-20t/h

Rated thermal efficiency: 100-104%

Pressure: ≤3.82MPa

Available fuel: heavy oil, diesel, natural gas, city gas, etc.

Advantages of Gas(oil) Fired Integrated Steam Boiler

- High thermal efficiency The flue gas is heat exchanged through the spiral finned tube in the condenser and economizer, so the heat transfer effect is stronger, the fuel consumption is reduced by at least 4%, and the thermal efficiency is increased to 104%.

- The insulation measures are perfect Ultra-fine glass wool is used as insulation material between the smoke box and the tube sheet, and the heat loss is extremely small, reducing unnecessary heat waste.

- Long service life The boiler body is made of a more corrosion-resistant material such as silicon-aluminum alloy. The combustion chamber is completely immersed in water and is not affected by high-temperature flue gas. So, the operating environment of the boiler is guaranteed.

- High safety factorVarious protection systems such as excessive water level, unstable pressure, abnormal power supply, scale detection, and burner system ensure the safety of boiler operation.