4 ton gas steam boiler price ,4 ton gas steam boiler factory configuration – boiler body, burner, control cabinet, water pump, water treatment equipment, economizer, condenser, sub-cylinder, chimney flue, primary valve instrument, etc.

The price of 4 ton gas steam boiler – the key depends on the configuration of auxiliary machines. As the saying goes, auxiliary machine configuration is king, and it is not bad at all. Originally, gas-fired boilers produced by different manufacturers have different thermal efficiencies and different operating conditions. The quality of the boilers has been separated here. Coupled with the difference in auxiliary machine configuration, the gap is even more obvious.

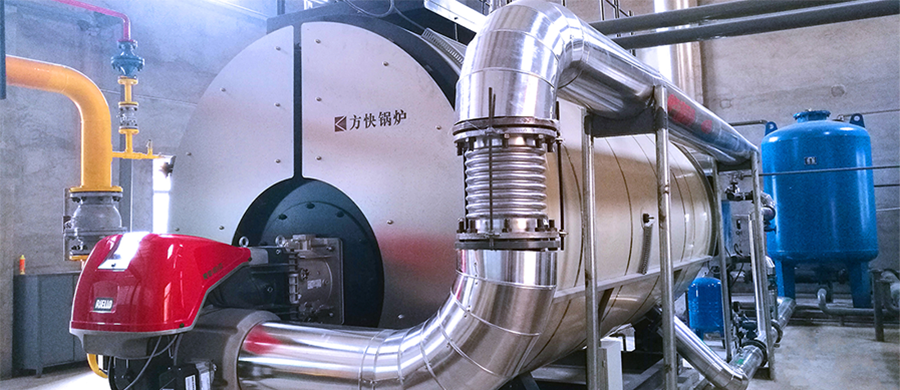

4 ton ultra-low nitrogen gas steam boiler of Institute of Traditional Chinese Medicine

WNS series 4-ton gas steam boiler, this series of boilers is a boiler product developed by our company and German technology. All products of this boiler type are factory-assembled to ensure that the boiler can be quickly installed on the user’s site. Except for the electrical connection accessories, no other building structures and special installation procedures are required. A series of testing and debugging work have been carried out before the boiler leaves the factory to ensure the quality of the boiler. WNS series gas boilers are widely used in fuel, and can use gas, natural gas, liquefied gas, biogas and other gases as fuel.

It is widely used in chemical industry, food industry, pharmaceutical industry, building materials industry, clothing industry, textile industry, packaging industry and other industries.

4 ton gas steam boiler technical parameters:

Boiler model: WNS4-1.25-Q

Design pressure: 13kg pressure

Rated evaporation t/h : 4

Rated steam pressure Mpa: 1.25

Rated steam temperature °C: 194

Applicable fuel: light oil, heavy oil, gas, gas

Light fuel consumption kg/h: 253

Heavy fuel consumption kg/h: 238

Natural gas consumption Nm3/h: 285

City gas Nm3/h : 610